When and why should I use spray powder for 3D scanning?

At last, a spray powder you don’t need to clean up!

We’ll let you in on a well-kept secret: regardless of what anybody says, using a coat of spray powder on an object for 3D scanning will always help the process; it’s not always necessary, but it is an ideal part of the process. A matte white surface allows for ultimate light detection and leads to optimal, quality 3D scan results. This is especially useful if you are trying to scan clear material, pitch-black objects or shiny metal parts.

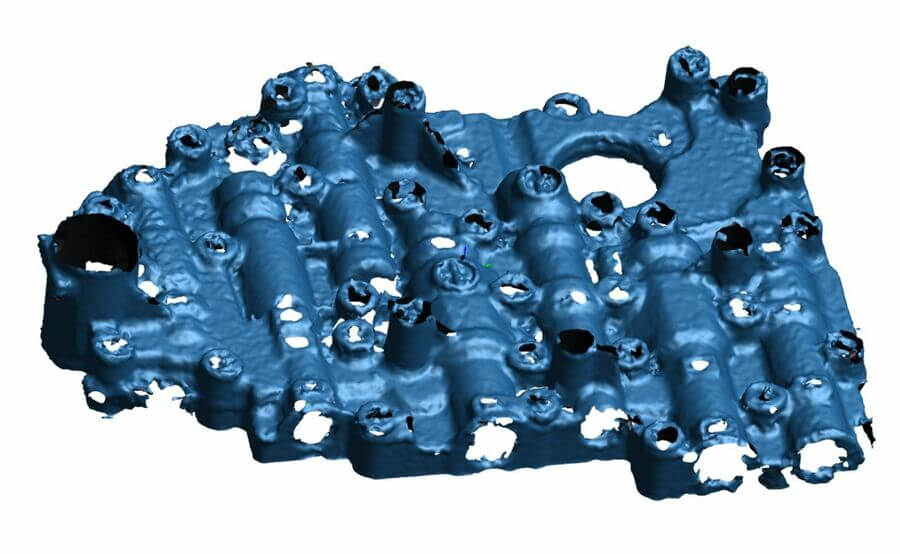

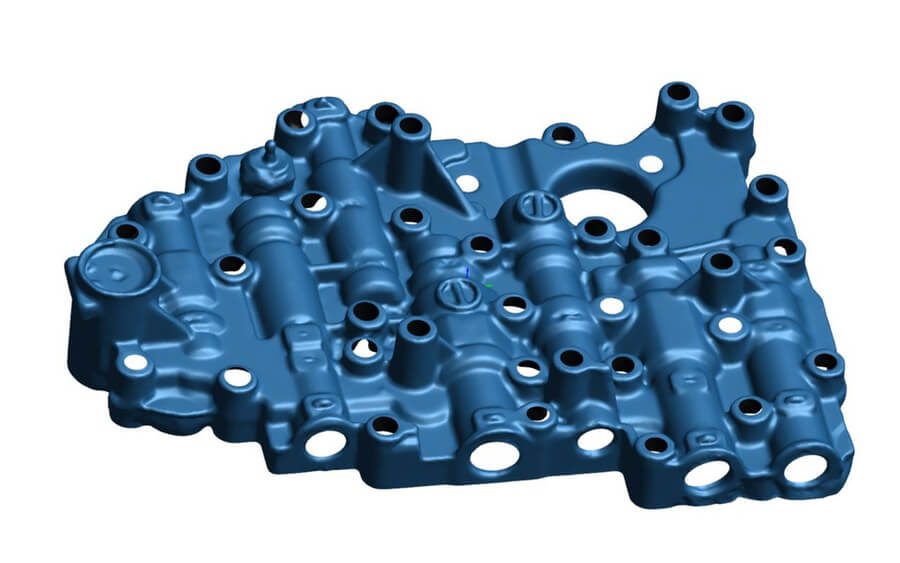

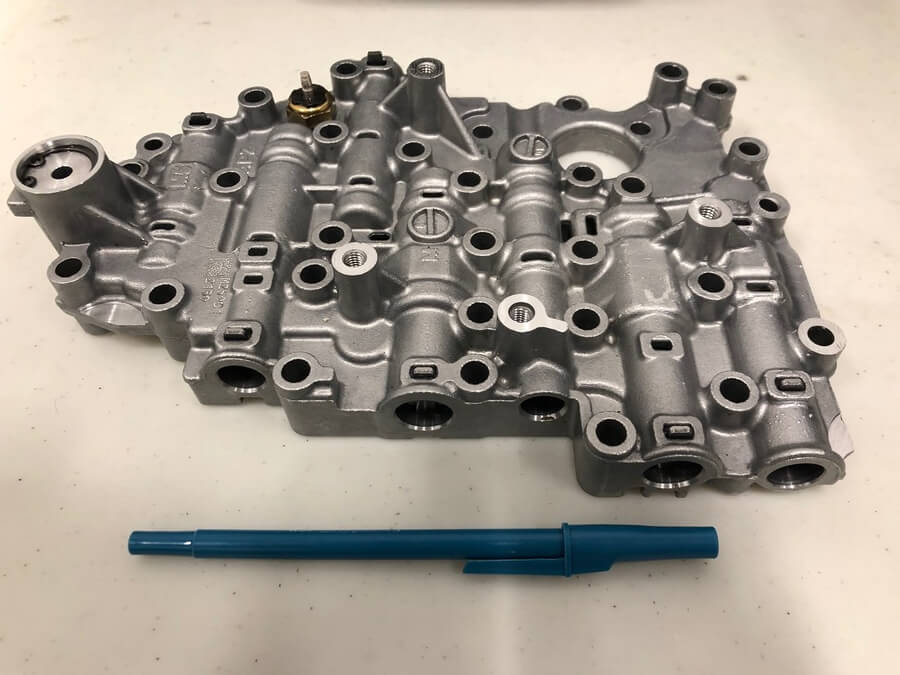

Here is an example of a highly challenging object scanned with a Peel 2—with and without spray powder:

Part scanned directly, without spray powder.

The same part was scanned with a coat of spray powder.

Actual part for reference.

Interested in 3D scanning?

Contact our Peel 3D expertsAs shown, the difference is staggering and dramatically affects how usable the 3D scanning data is.

Convinced? If so, you might now be wondering what options you have.

Vanishing sprays:

These sprays are made of a fine powder that sublimates over time; it stays on for a few hours and progressively disappears to leave the part as clean as it was at the start. This is indeed as neat as it sounds.

We have tested two sprays: Cyclododecane Spray and AESUB Vanishing 3D Scanning Spray.

Both options work equally well and create a highly suitable matte white coat over the surface. The Cyclododecane Spray tends to be a lumpier, somewhat like a thicker, slightly bumpier coat of frost on your object. The AESUB Spray was very uniform, easy to apply and, therefore, our favourite.

You can see the magic in action here.

Semi-permanent options:

Of course, one of the inconveniences of using a vanishing powder is that it will eventually vanish! If you wish to leave it on for a while so you can scan over a few days, for example, you should go for a longer-lasting option; in any case, you can always wash it off later.

Our favourite option is Magnaflux SKD-S2. It is easy to apply and spread evenly on the part. It leaves a perfectly uniform layer of white powder. Overall this is the best option if you don’t mind cleaning the part up afterwards; it’s also cheaper.

Permanent options:

Another alternative that works very well is simply to use a primer; white or grey will work best. Of course, primer is meant to stay on whatever surface you apply it to, so there’s no cleaning option. It should still be a consideration that depends on the situation as it is a mess-free solution and the cheapest option.

Armed with these solutions, you should be able to turn any challenging material into an actual 3D scanning work of art.

Wonder how Peel 3D can transform your work, solve problems, and save you time?

Contact our Peel 3D expertsauthor

ABOVE MENTIONED PRODUCTS