Transforming Healthcare with Peel 3D Scanning at Parc Taulí

Origins of This Initiative

The integration of 3D technology at Parc Taulí Hospital was driven by the passion of Dr. Ferran Fillat, an orthopedic surgeon specializing in 3D digital surgery. Dr. Fillat serves as the medical director of the hospital’s 3D Laboratory (3DLab) and is the founder of Tailor Surgery, a spin-off focused on advanced medical applications. His research initially centered on using 3D printing to classify humerus fractures for his doctoral thesis, opening new possibilities in traumatology and beyond.

Breakthroughs During the COVID-19 Pandemic

The pandemic highlighted the transformative potential of 3D technology in medicine. Dr. Fillat's team leveraged 3D scanning and printing technologies to manufacture respirators, ensuring rapid and efficient delivery to hospitals across Spain. This demonstrated the superiority of 3D technology over conventional diagnostic methods by enabling the rapid creation of physical objects for diagnosis and treatment.

Expansion and Collaboration

Establishing a 3D lab in a hospital requires more than just technology, such as 3D scanners, 3D printers, and design software. It also demands medical professionals who understand patient needs and technical engineers proficient in device operation. Both roles must collaborate to address medical challenges effectively.

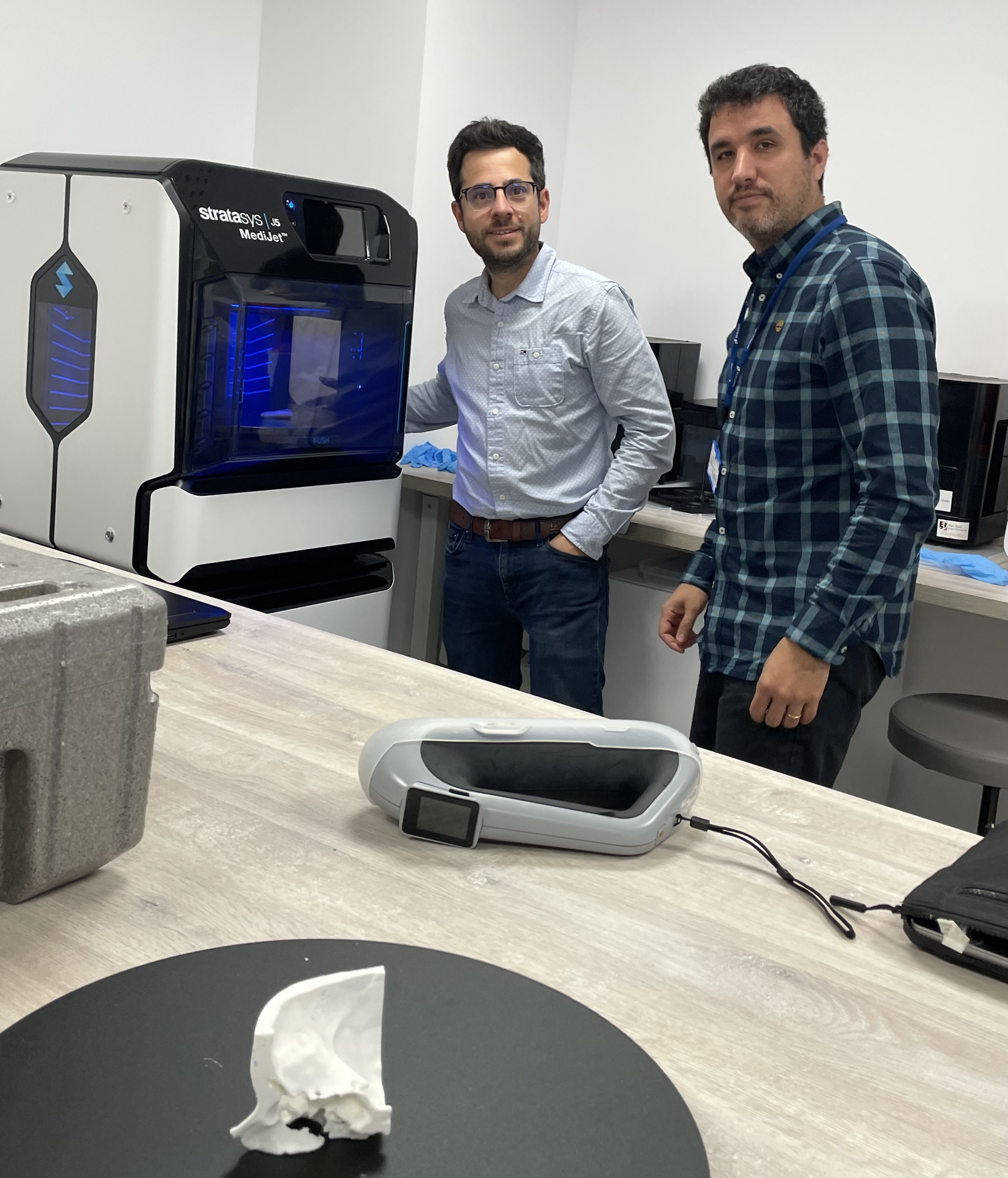

Toni Nadal, lab coordinator at Parc Taulí’s 3DLab, brings his expertise as a biomedical engineer and medical device specialist with extensive knowledge of 3D technology. Today, the hospital’s 3DLab team leads projects across multiple medical specialties, including nursing, general surgery, and cardiology.

Building on its success, Parc Taulí has established partnerships with other hospitals, such as Hospital Clínic in Barcelona, to support the development of additional 3D labs. Institutions including Vall d’Hebron, Sant Pau in Barcelona, Terres de l’Ebre Clinic in Tarragona, Gregorio Marañón Hospital in Madrid, and Virgen del Rocío University Hospital in Seville are already following Parc Taulí’s lead in integrating 3D technology.

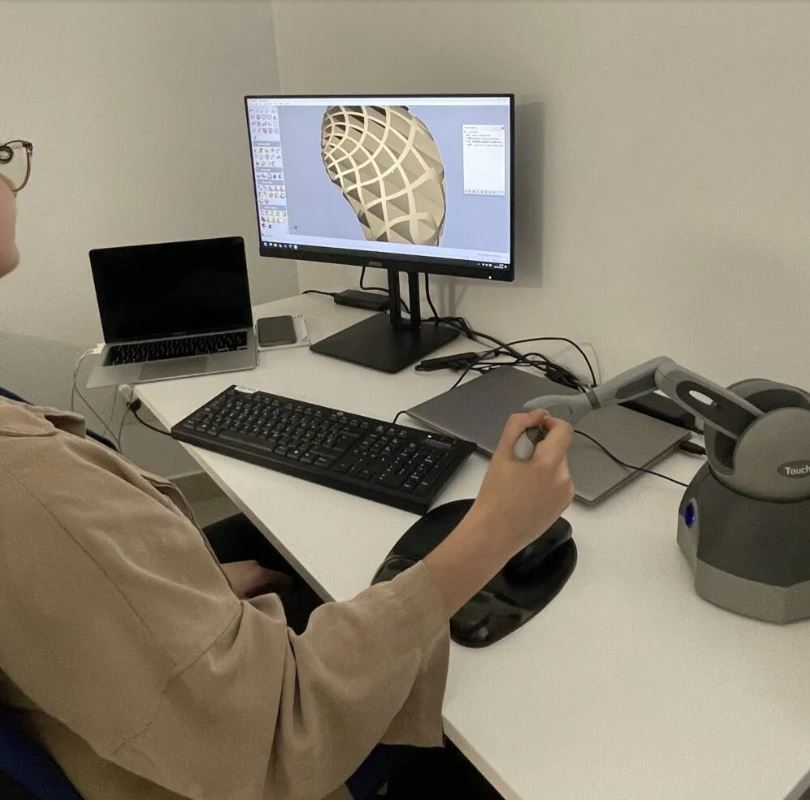

Software and haptic device at Parc Taulí’s 3DLAB

Surgical Applications of 3D Scanning

One of the most significant advancements has been the production of single-use, customized surgical guides. These guides help surgeons perform precise incisions and cuts, significantly improving accuracy in surgical interventions. The guides are tailored for each patient using, advanced 3D scanners, specialized 3D software, and high-precision 3D printers.

The process involves:

- Medical Imaging – A CT scan of the affected area is performed.

- 3D Conversion – CT images are converted into 3D models for generating CAD designs from CT scans.

- Scanning with Peel 3D – The Peel 3 3D scanner scans implants and other components involved in the procedure.

- Surgical Simulation – The 3D models allow for a detailed pre-surgical simulation, testing various scenarios.

- Manufacturing Custom Tools – Once the optimal approach is identified, high-precision 3D printers create the customized surgical guides for each patient.

Traditionally, prostheses were manufactured in approximate sizes and adjusted in the operating room, leading to prolonged surgery times, higher infection risks, and longer recovery periods. With 3D scanning and printing, prostheses can now be custom-designed in advance, significantly reducing surgery time and associated risks.

Key Benefits of 3D Technology in Healthcare

The implementation of 3D scanning and printing in hospitals offers numerous advantages, including:

- Reduced Infection Rates – Faster surgeries minimize the risk of postoperative infections.

- Cost Savings – Shorter surgery durations reduce operational costs.

- Material Efficiency – Only necessary instruments are sterilized, preventing unnecessary waste.

- Improved Patient Outcomes – Fewer complications lead to faster recovery times.

3D printer and Peel 3 scanner at 3DLAB

The Future of 3D Technology in Medicine

The adoption of 3D technology has already demonstrated significant benefits, from optimizing hospital resources to reducing surgical risks. Dr. Fillat envisions a future where all surgeries are planned using virtual simulation, integrating 3D tools into daily medical practice.

Next steps for Parc Taulí’s 3DLab include:

- Developing Certified Biocompatible Materials – Enhancing safety and compatibility for medical applications.

- Automating Processes – Increasing efficiency and sustainability in healthcare.

AsorCAD’s Role in Advancing Medical 3D Technology

This article has been provided by Rosa Alonso, Director of Marketing at AsorCAD, Parc Taulí’s partner in Spain. The hospital’s decision to collaborate with AsorCAD was based on the quality and reliability of its 3D scanning and printing solutions, essential for demanding medical environments.

AsorCAD and its represented brands not only supply advanced technological tools but also provide agile and effective support, ensuring continuous and efficient operations within the healthcare sector.

According to Toni Nadal, "Knowing the impact of 3D technology in healthcare, I believe it would be unethical not to use it. It would be like building houses without architectural plans."

Parc Taulí’s commitment is clear: to revolutionize healthcare through technological innovation, ensuring every surgery is planned with precision.

Article by Rosa Alonso

Director of Marketing, AsorCAD

Wonder how Peel 3D can transform your work, solve problems, and save you time?

Contact our Peel 3D experts