Revolutionizing Cranial Orthoses: How Ottobock and Peel3D Are Transforming Digital Healthcare

In the healthcare sector, innovation is key, and Ottobock is leading the way. As a trusted partner of Peel 3D, Ottobock has successfully integrated our advanced 3D scanning solutions into their manufacturing process, enabling the creation of highly customized, patient-specific devices. Together, we recently hosted a webinar to introduce the MyCRO Band and showcase how cutting-edge 3D scanning and printing technologies are reshaping orthotic and prosthetic care.

The MyCRO Band: A Milestone in Digital Healthcare

As the first FDA‑approved 3D‑printed cranial molding orthosis available in the U.S., the MyCRO Band received clearance in March 2021. Since then, more than 6,000 MyCRO Bands have been produced for infants across the United States. What makes this achievement remarkable is that the entire fabrication process is fully digital, ensuring unmatched precision, efficiency, and patient comfort.

While the webinar focused primarily on cranial molding orthoses, this digital workflow can be applied to a wide range of orthotics and prosthetics (O&P) devices. If you’ve attended recent O&P conferences, you’ve likely noticed the growing presence of 3D-printed solutions due to their ability to deliver superior accuracy and customization compared to traditional methods.

The Digital Workflow: Three Simple Steps

The MyCRO Band fabrication process consists of three main steps:

- Scanning: Using a high-quality Peel 3 3D scanner, clinicians capture an accurate scan of the baby’s head.

- Design: The scan file is uploaded to Ottobock’s custom fabrication platform, where the CAD model of the MyCRO Band helmet is created.

- Fabrication: The finalized design file is sent to a 3D printer for production, completing the fully digital workflow.

Why 3D Scanning Matters

Ottobock understands the importance of equipping medical professionals with advanced tools to deliver perfectly fitted, individualized helmets. The Peel 3 scanner is ideal for cranial scanning because it can accurately track babies’ heads, even if they are moving.

Beyond cranial orthoses, 3D-scanning has broad applications in prosthetics, pediatrics, mastectomy, plastic and cosmetic surgery, and foot orthotics. For example, in cosmetic surgery, a patient can be scanned before and after a rhinoplasty, and the differences visualized using a color map.

For foot orthotics, capturing both the top and bottom of the foot is essential. This can be achieved using plexiglass frames with strategically placed targets, allowing you to scan from multiple angles and then align and edit the data.

Compared to traditional prosthetic fabrication, which involves casting, plaster filling, shipping, and multiple adjustments, digital scanning eliminates inefficiencies, reduces delays, and improves accuracy.

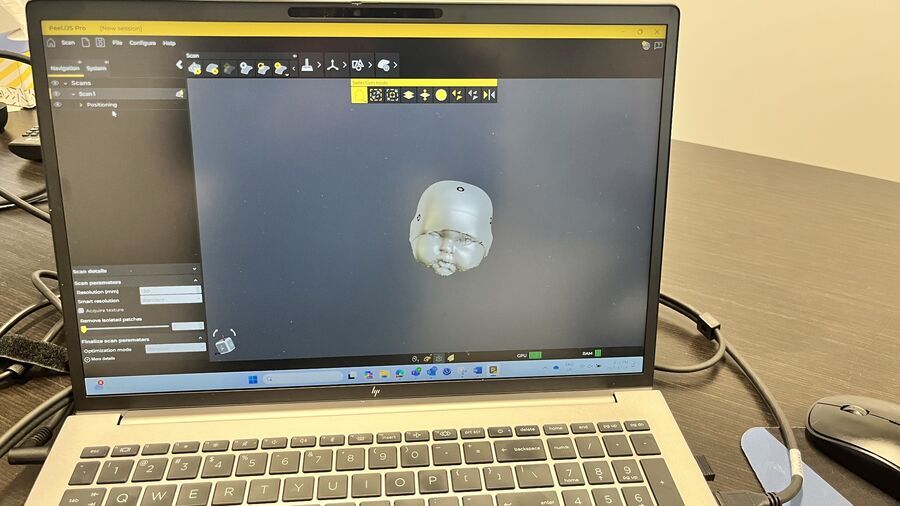

Peel 3D Demonstration: 3D Scanning Made Simple

During the webinar, our team demonstrated a cranial scan using the Peel 3 technology. The workflow is straightforward: Connect the scanner to a computer and power source, launch the software, calibrate, and set the following parameters:

- Object type: Human body

- Color: Optional

- Resolution: ~2 mm

- Smart resolution: Off

- Watertight: On

Target markers help maintain tracking during scanning. Once complete, the mesh is cleaned using Peel.OS tools, which removes spikes, fills holes, and isolates the head for export. The final file (STL or OBJ) is then uploaded to Ottobock’s platform for design and production.

The MyCRO Band Advantage

Digital fabrication offers numerous benefits:

- Precision: Perfect fit for every patient.

- Material Innovation: PA12 powder transforms into rigid nylon after printing, making helmets strong, lightweight, and heat-moldable.

- Efficiency: Up to 60% thinner and 40% lighter than conventional helmets.

- Aesthetics: Improved design

- Sustainability: Reduced waste, as PA12 powder can often be reused.

Design Highlights

- Open-top design for breathability and reduced weight.

- Removable fabric lining for easy cleaning (two liners included).

- MySize closure system for head growth accommodation.

- Grip zones for stability and rotation prevention.

MyCRO Bands are printed in gray but can be dyed blue or pink. Ottobock also offers 40 emblem designs for engraving and customization options like acrylic painting.

Empowering Clinicians

Ottobock’s ordering platform allows clinicians to generate detailed measurement reports, track treatment progress, and overlay initial, mid-treatment, and final scans. This data can be shared with insurance providers for verification. New users complete an online certification before scanning and ordering. Ottobock also provides remote follow-up sessions with their experts to ensure success.

The Future of O&P Care

The partnership between Ottobock and Peel3D demonstrates how digital technologies are reshaping healthcare by delivering better outcomes, faster workflows, and more personalized care. As adoption grows, patients and clinicians alike will benefit from the precision and flexibility of 3D scanning and 3D printing.

Wonder how Peel 3D can transform your work, solve problems, and save you time?

Contact our Peel 3D experts