Precision and Comfort: The Journey of Customized Orthopedic Shoes

Duna was established in 1974 by Franco Rosiglioni, who continues to serve as the company's president, as a small artisan enterprise specializing in orthopedic footwear for children. From its inception, the company quickly distinguished itself as a reference point in the sector.

Over the years, Duna has significantly broadened its scope, incorporating the production of both custom-made and mass-produced orthopedic footwear for adults. In addition, the company has developed and launched a technologically advanced production line to support the manufacturing of orthopedic shoes and insoles.

Today, Duna is widely recognized as a leading authority in the orthopedic footwear industry, not only in Italy but also throughout Europe and in international markets.

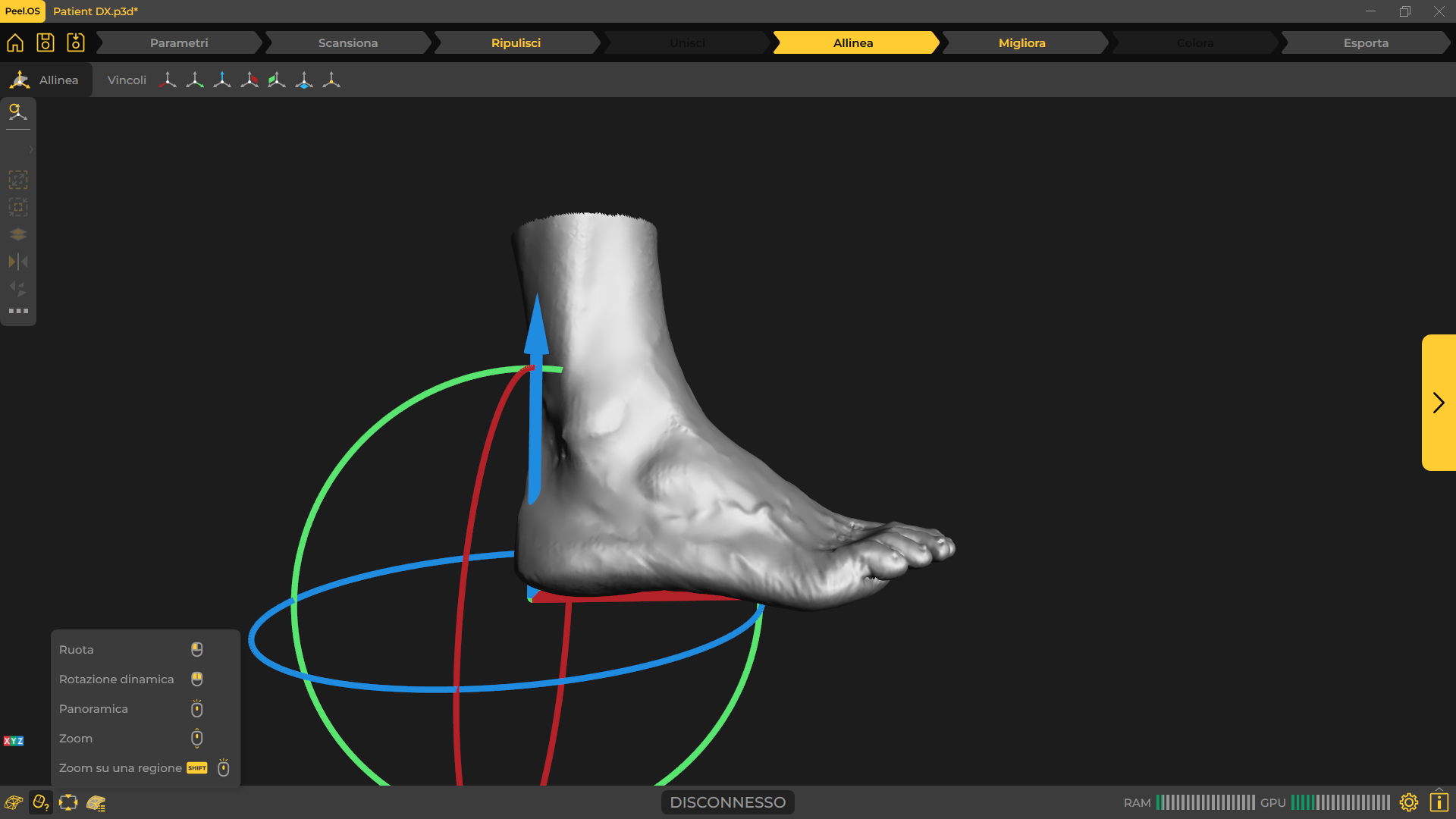

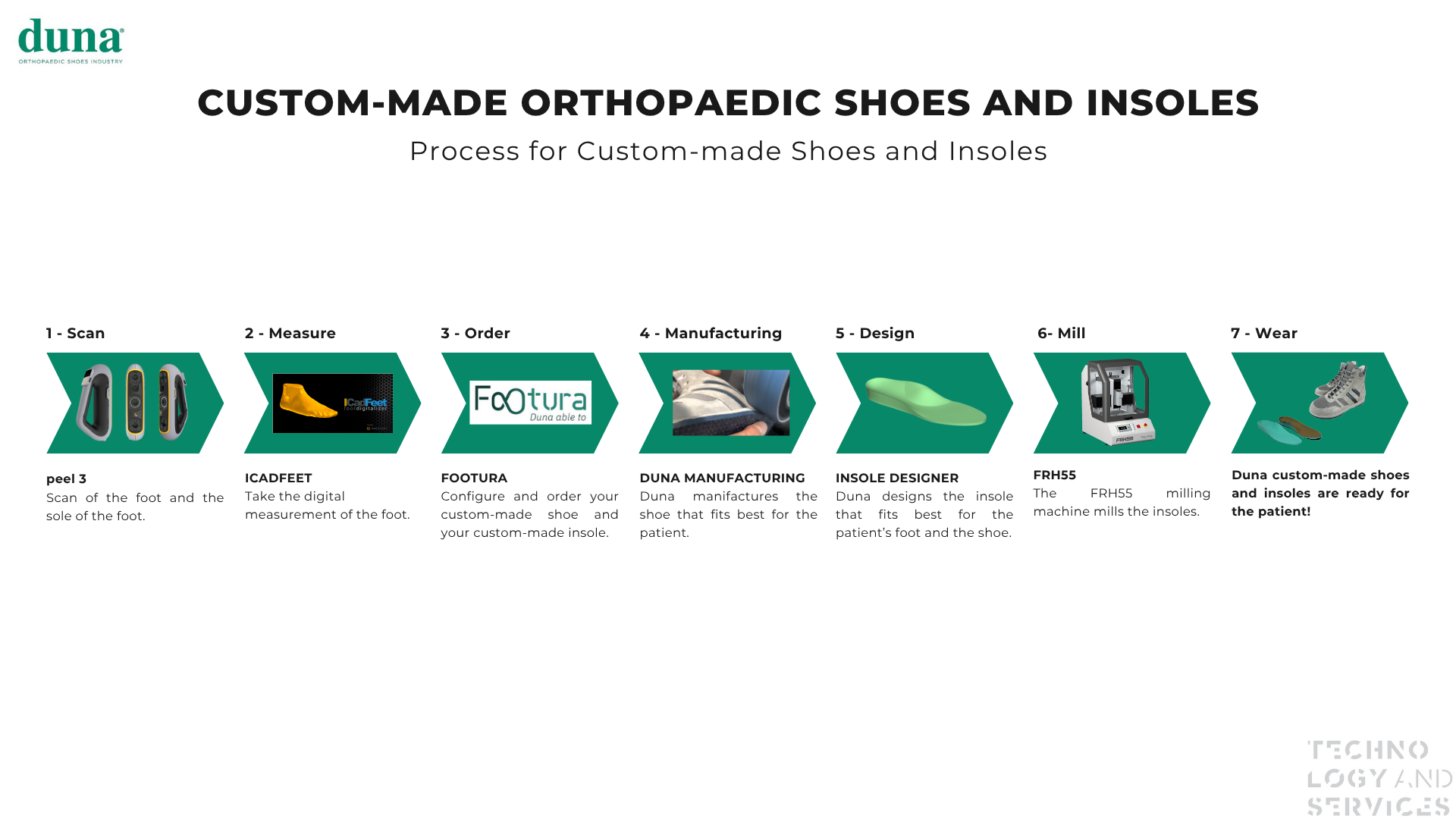

The process used by Duna for manufacturing custom-made shoes begins with the 3D scan of the foot using the Peel 3 handheld 3D scanner. During the scanning procedure, the operator must move around the patient’s foot to capture its complete volume.

The Peel.OS software plays a crucial role in ensuring accurate mesh cleaning and proper scan orientation, with the foot’s sole aligned along the XY plane.

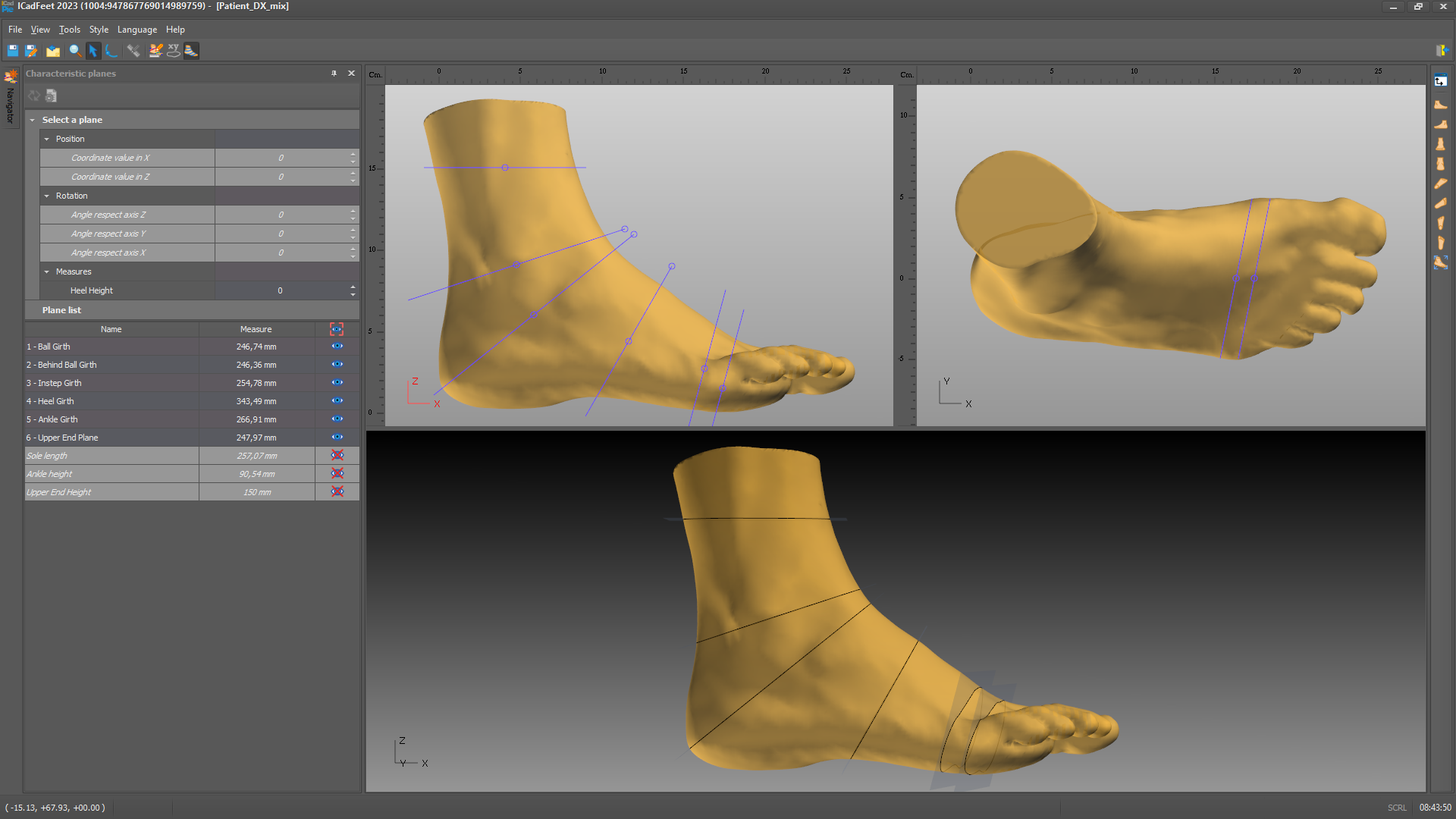

Once the scan is finalized, the resulting STL file is imported into ICadFeet, a specialized software developed collaboratively by Duna and its partner Inescop. ICadFeet is designed to analyze foot volumetry and extract precise measurements. A distinctive feature of this software is its ability to define inclined planes, whose intersections with the foot generate key circumferences. These measurements, traditionally obtained manually, are now derived digitally, enhancing both accuracy and efficiency.

A precise 3D reconstruction of the foot is essential, particularly in cases involving pathological conditions, as it significantly contributes to achieving an optimal fit and minimizing the risk of production errors.

The data is subsequently imported into Footura, a web-based application developed by Duna, which offers a wide range of technical and aesthetic configuration options for orthopedic footwear. Once the technician finalizes the design specifications, Footura transmits the order to Duna, where the shoes are designed and manufactured. The entire process typically requires approximately 3 to 4 weeks for completion.

The customization of orthopedic footwear plays a vital role in promoting the well-being of patients requiring preventive care or treatment for specific foot pathologies. These specialized shoes are meticulously designed to support the biomechanics and structural integrity of the foot, ankle, and leg, providing effective solutions for conditions such as hallux valgus, plantar fasciitis, diabetes-related complications, or for accommodating orthopedic braces.

Duna’s approach significantly shortens the time between the initial measurement and the moment the patient receives their custom footwear. This streamlined process minimizes the need for post-delivery adjustments or remakes, ensuring a precise fit from the outset.

Insoles represent a fundamental component of orthopedic footwear. Similar to the shoe manufacturing process, the production of insoles begins with the acquisition of the foot’s volumetric data. This is achieved using the Peel 3 3D scanner, followed by post-processing in the Peel.OS software to ensure a clean and properly oriented model.

The processed scan is then imported into Insole Designer, a proprietary plug-in developed by Duna for use within the Rhinoceros CAD environment. This tool enables the precise digital design of the insole. Once the design is finalized, the insole is fabricated using a milling machine. The final steps involve covering and finishing the insole before it is integrated into the footwear.

The result is a fully customized combination of shoe and insole, tailored to the patient’s anatomy, ensuring optimal alignment and comfort through a seamless match between foot, insole, and shoe.

Peel 3D has proven to be the leading brand of 3D scanners in the medical sector. It is the preferred choice of numerous renowned clinics and companies worldwide for capturing patient measurements, whether of the limbs, torso, or head, in order to correct and improve the effects of various medical conditions.

If you would like to gain further insights into these processes, we encourage you to watch the recording of our recent webinar, held in partnership with Duna, by following the link below:

Precision and Comfort: The Journey of Customized Orthopedic Shoes

Wonder how Peel 3D can transform your work, solve problems, and save you time?

Contact our Peel 3D experts