From Scan to Street: How 3D Scanning Is Reshaping Motorbike Accessory

Motorbike-accessory engineering rises or falls on the quality of each part’s geometry. When a component must clear a brake rotor by only a few millimetres, even a minor dimensional drift forces costly rework. Peel 3D’s scanner, paired with Peel.CAD Pro software strips the uncertainty out of that process.

By capturing accurate surface data in minutes and providing mesh-editing and modeling tools within a single environment, these solutions help small teams go from concept to street-ready parts in days, not weeks.

When a Garage Startup Turns into In-House R&D

Bagoros Performance began in a rented garage where parts were cut, welded and ground by eye. Nine years later, the company occupies a purpose-built facility, runs its own five-axis machining centre, and validates every design on KTM- and Ducati-based test bikes piloted by co-founder and stunt rider Rok Bagoroš.

A design turning point came when the team adopted Peel 3 and Peel.CAD Pro; accurate scans replaced manual 3D measurements. The downstream gains were instant. A single afternoon’s work now delivers a watertight mesh, a parametric CAD model and a printed prototype that almost always fits the first time it touches the motorcycle.

How Peel 3 and Peel.CAD Pro Compress Lead-Time and Cost

The Peel 3 system lowers costs on two fronts. First, it cuts scanning time to well under an hour for an entire engine case or frame section, which means engineers can redirect days of manual measurement toward design work.

Second, it reduces errors that previously surfaced only after the aluminum had been machined. Because the first printed prototype already mirrors the motorcycle within tenths of a millimetre, Bagoros Performance no longer wastes as much material or rework on mis-sized parts; production moves faster than ever before.

Mesh-Editing Tools That Solve Real-World Problems

Once a scan lands in Peel.CAD Pro, engineers refine the mesh before any solid geometry is created. If the surface contains an opening, such as perhaps a small void between spokes or a gap left by an inaccessible recess, the Fill Hole feature closes it instantly, returning a manifold mesh that can be sectioned without artifacts.

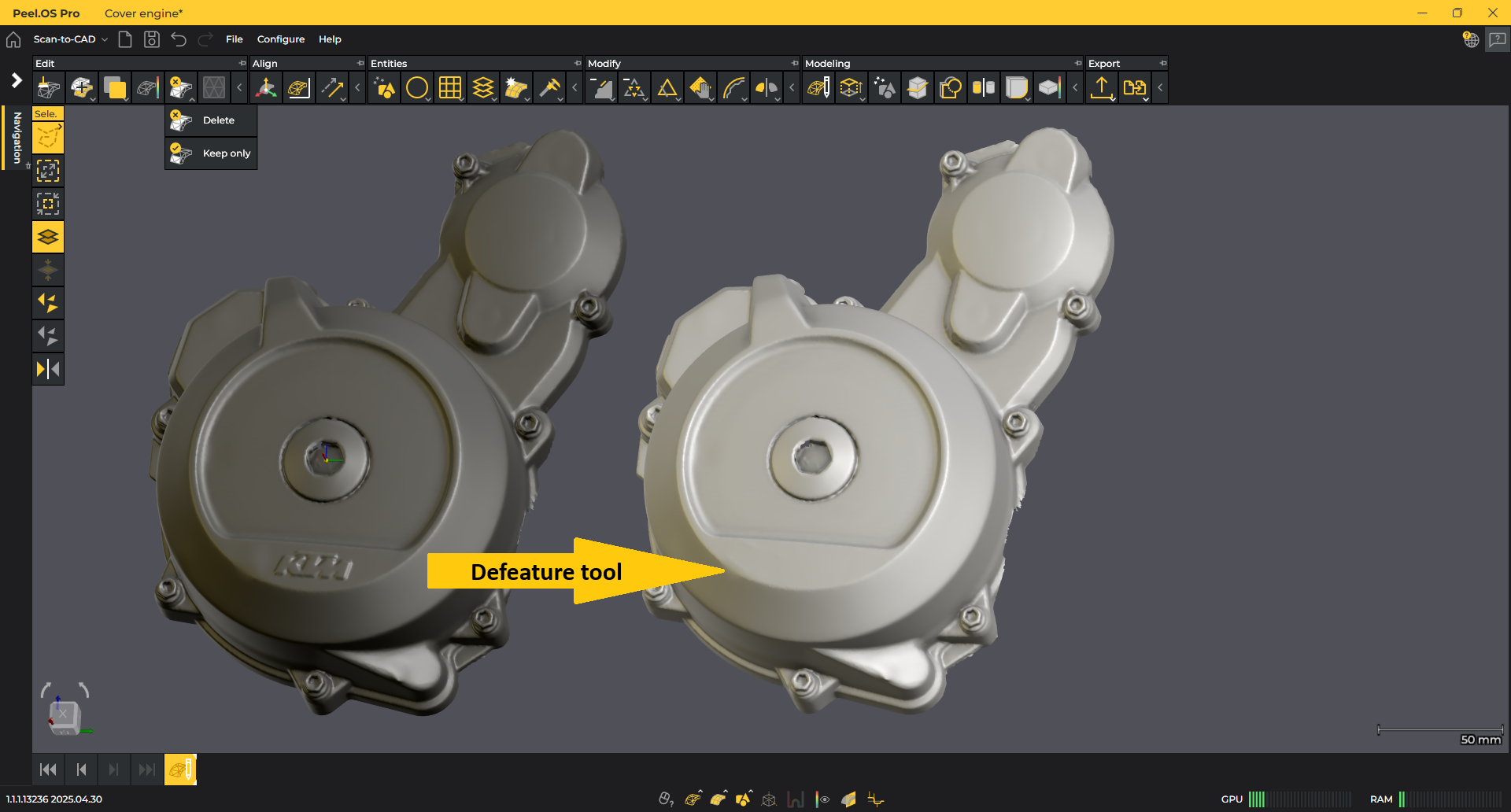

Brand markings raise a different kind of challenge. For example, when working on a KTM engine cover where the cast-in logo stood proud on the surface, which is great for branding, but a nightmare for reverse engineering. That raised lettering can throw off feature recognition, especially when trying to extract clean planes or revolve profiles. In the past, Bagoros would export the mesh, fire up a third-party sculpting tool, and spend the better part of an hour manually smoothing it out. However, Peel.CAD Pro includes the 'Defeature' tool which effectively addresses these challenges. One click, and the software intelligently removes the logo, re-stitching the surrounding triangles like it was never there. What’s left is a smooth, uniform surface that mimics bare aluminum—perfect for downstream CAD work. It’s not just a time-saver; it’s a workflow revolution.

Modelling Directly on the Mesh

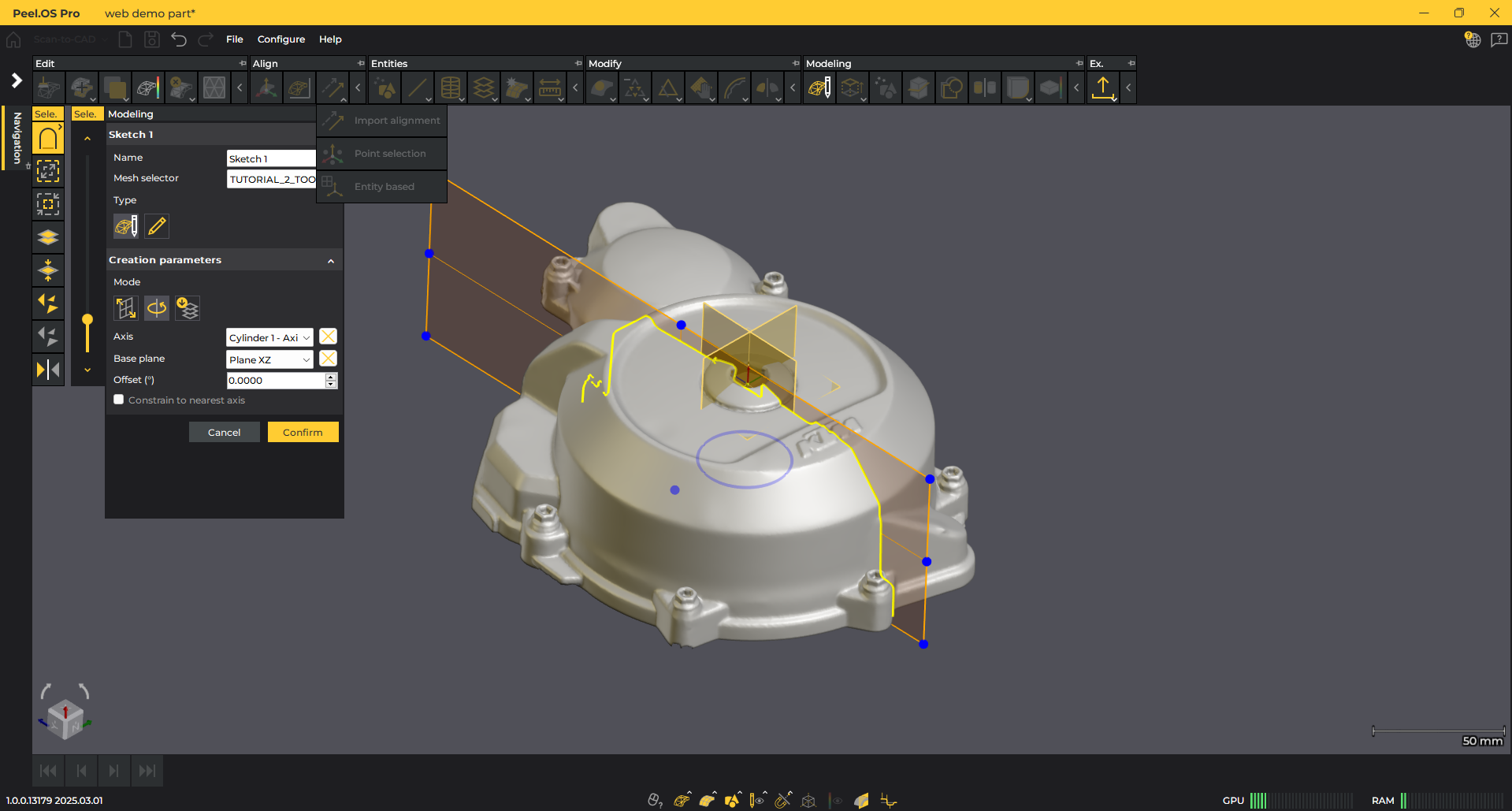

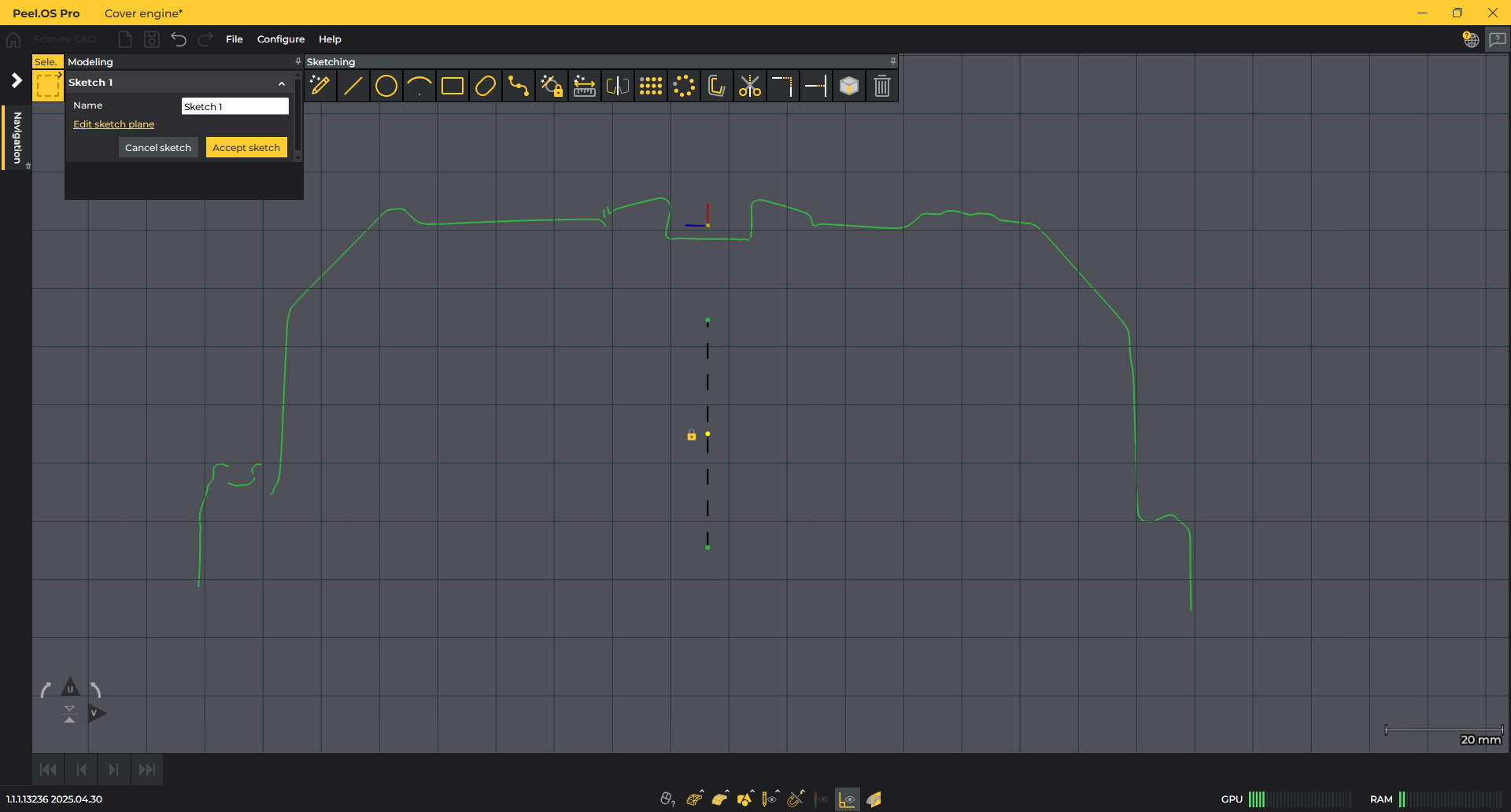

With the scan now cleaned and defeatured, it is time to move from mesh to model. The engineer activates sketching mode and extracts a reference profile by selecting a cylinder and an intersecting plane on the mesh. Peel.CAD Pro then automatically generates an auto sketch: a 2D profile extracted directly from the mesh. It drops onto the sketching canvas like a blueprint, with vertical and horizontal constraints already applied to lock key lines.

A few tweaks later, after tightening a radius here and adjusting a tangent there, the sketch is ready to revolve. With a single command, it spins around its centerline, forming a precise solid body that mirrors the original engine cover. This solid isn’t just a replica—it’s a foundation. From here, the team can design the accessory that mounts to it, whether it’s a crash bobbin, a bar-end mirror clamp, or a custom three-caliper brake bracket. What used to take days of guesswork and manual modeling now flows naturally from scan to solid.

Closing the Loop with Deviation Analysis

Before the model ever leaves Peel.CAD Pro, the final quality check kicks in. The software runs an automated comparison between the newly created solid and the original scan mesh. It’s a crucial step, and one that used to require exporting to a separate metrology suite. Now, it’s built right in. A colormap deviation plot lights up the screen, flagging any region that strays beyond our tolerance band, typically ±0.1 mm for motorcycle components.

If a surface bulges too far or sits too shallow, the user can nudge it directly within the same session and re-run the analysis in seconds. No exporting, no guesswork. By the time the file is ready for the 3D printer or the five-axis mill, the team knows it’s going to fit. No shims, no grinding, no post-machining tweaks. Just a part that seats flush against the real bike—first time, every time.

Crash-Bobbins: A Practical Example

Developing a crash bobbin used to consume more than a week. Engine studs were measured by hand, a bracket was machined, and the first installation frequently revealed misalignments that forced a second or third aluminum blank.

With Peel 3D, the studs, engine cover and surrounding frame are scanned in half an hour. Mesh tools close any gaps and strip unneeded branding; modelling tools extract the mounting profile and revolve the bracket geometry; the deviation check confirms fit; and a printed prototype bolts on the same day. In most cases, the first billet unit leaves the CNC machine forty-eight hours later and heads straight to anodizing, with no scrap generated along the way.

Triple-Calliper Rear-Brake Bracket: Accuracy Under Pressure

Stunt riders often demand three independent rear brakes on a single rotor. The bracket that carries those callipers must centre each unit within a few millimetres of the disc face.

Bagoros Performance once produced five failed versions before the geometry finally aligned. The Peel 3D workflow solved the problem in a single cycle: scan the hub, extract mounting planes, revolve the bracket, verify clearance on-screen, print, and ride-test. No aluminum was wasted, and the calipers lined up perfectly on the first metal cut.

Quantified Business Impact

Across the product line, Peel 3D and Peel.CAD Pro have reduced development lead time from ten days to as little as two, cut prototype costs by over sixty percent, and nearly eliminated rework.

The resulting schedule margin lets the team tackle additional SKUs without adding staff or machine capacity—an outcome that turns capital equipment into a competitive advantage rather than a fixed cost.

Extending the Workflow to Restoration

Although Bagoros Performance focuses on new accessories, the same toolchain can reproduce legacy engine cases or fairings that no longer exist in the supply chain.

A cracked casting is scanned, cleaned using Fill Hole and Defeature, remodeled through sketch-and-revolve, and verified for fidelity. The replacement part then emerges from billet or additive powder with the same geometry—and often greater strength—than the original.

In conclusion, for companies that require highly accurate fits, consider Peel 3 D and Peel.CAD Pro have moved beyond convenience. These integrated 3D scanning technologies reduce lead-time, cut costs, eliminate first-article errors and deliver a perfect fit on the first attempt.

Bagoros Performance’s experience demonstrates how a small team can utilize these tools alongside in-house printing and machining to produce professional-grade accessories at a speed and profit margin that would have been unattainable only a few years ago.

Interested in learning more? Watch Bagoros Performance’s recent presentation.

Wonder how Peel 3D can transform your work, solve problems, and save you time?

Contact our Peel 3D experts