From 3D Scans to Life-Changing Prosthetics: Peel 3D in Action

In Mongolia, where vast landscapes stretch for miles and communities are often scattered and remote, accessing quality healthcare can be a real challenge, especially when it comes to prosthetics. Until recently, many Mongolians with limb differences were limited to basic, silicone sleeves that looked acceptable but provided little assistance in daily life. They deserved better.

That’s exactly what inspired Mongolian Prosthetics: a mission to create affordable, functional prosthetic hands that could truly change lives without costing a fortune.

Mongolian Prosthetics is a collaborative initiative driven by the Fulbright Program, working closely with Mongolian healthcare providers, non-profits like the Oddariya Foundation, and local universities. Dedicated to transforming the quality and accessibility of prosthetic care in Mongolia, this project aims to produce affordable, customizable, and highly functional prosthetics tailored specifically to Mongolia’s unique environment and culture.

In Mongolia, approximately 56,000 people are in need of prosthetic or assistive devices, yet current local prosthetic manufacturers can only reach about 3% of this population. Traditional options are either prohibitively expensive ($400–$600) or affordable but largely ineffective ($160 for imported resin prosthetics).

Given Mongolia’s economic reliance on physically demanding industries, the lack of practical prosthetic solutions severely limits opportunities for individuals with limb differences. However, the Mongolian Prosthetics project has demonstrated the capability to produce comfortable, customized, and highly functional prosthetics for less than $50 in under 24 hours, making meaningful participation in work and daily life attainable for thousands more Mongolians.

How? Through advanced technologies like 3D scanning and additive manufacturing.

Making a Real Difference with Simple Innovation

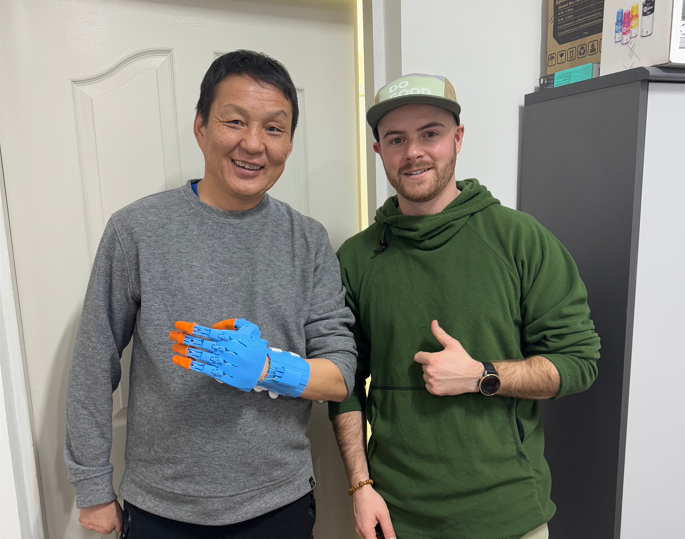

After months of hands-on research, trial-and-error testing, and some incredible teamwork with the National Rehabilitation Center of Mongolia, the Oddariya Foundation, and the Fulbright Program, the project reached a breakthrough. Today, for less than $40 and in just two days, patients in Mongolia can receive fully functional prosthetic hands tailored exactly to their needs.

Imagine the difference that makes—going from a passive, cosmetic sleeve to a hand that actually moves, grips, and lets you hold a cup, button a shirt, or simply write your name.

But how exactly is this possible? Surprisingly, it's simpler than you'd think. All it takes is equipment already found in Mongolia’s publicly funded prosthetics workshops, basic training (just one or two days!), a 3D scanner and a reliable 3D printer. Suddenly, complex prosthetic technology becomes accessible to everyone.

A prosthetic can now be created affordably thanks to 3D scanning and 3D scanning software.

Better yet, these prosthetics go beyond giving users new physical abilities. They also offer dignity, confidence, and independence, shifting perceptions in a society where stigma around disability can still linger.

Peel 3D’s Contribution to the Project

To make this solution even more effective, Peel 3D stepped up by donating a Peel 3D scanner as well as its integrated 3D scanning software. And it wasn’t just another piece of equipment or software. It was a game changer.

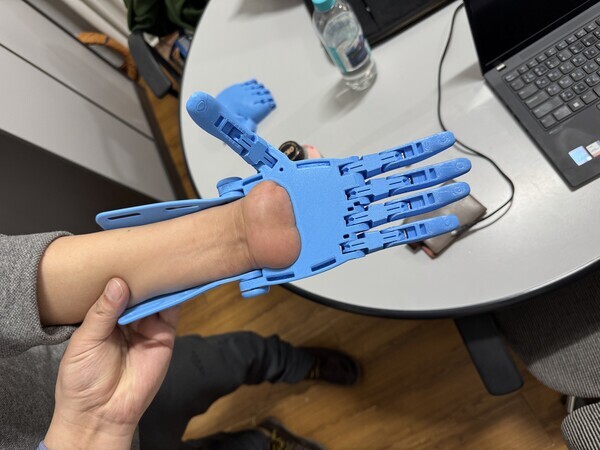

This portable, easy-to-use scanner can capture detailed 3D models of residual limbs in minutes. With impressive precision (we’re talking accuracy down to 0.25 mm), the Peel 3D scanner has allowed the team to produce prosthetics that fit comfortably and function smoothly.

Most importantly, it travels easily. Now, even the most remote communities across Mongolia’s rugged terrain can benefit from precision scanning and custom prosthetics. Gone are the days when patients had to travel hundreds of miles just to get measured.

Technicians use Peel 3D’s portable scanner to develop custom prosthetics.

Once the 3D measurements of the arm are imported into Peel 3D’s 3D scanning software, the data can be further processed and sent to a CAD solution to finalize the prosthetic’s design.

The Real-world Impact of 3D Measurement Technologies

With Peel 3D’s support, this project has accelerated dramatically. Prosthetic hands that genuinely change lives are now reaching Mongolians faster and in greater numbers than ever before. That means more everyday tasks made easier, more independence gained, and more lives transformed.

But this is just the beginning. The Mongolian Prosthetics Fulbright Project and Peel 3D are determined to keep pushing boundaries, bringing practical, affordable prosthetics to every community—and every person—who needs them.

Because technology truly makes a difference only when it’s within everyone’s reach.

Putting 3D measurement technologies to good use for the common good of people in Mongolia.

Wonder how Peel 3D can transform your work, solve problems, and save you time?

Contact our Peel 3D experts