7 things you should know about photogrammetry vs 3D scanning

Why pay for something when you can do it for free (or more affordably)?

Of course, nothing is entirely free. Even if you use free photogrammetry software, you probably still need to invest in a camera to take the pictures. And the question remains: why would you pay for something if there is a solution that lets you do it for free? It really depends on what you want or needs!

Here are the top 7 things you need to consider when deciding between photogrammetry and 3D scanning.

1. The all-forgiving textures

A high-resolution texture can sometimes have a very positive effect on the perception of a mesh. This is how the cinematic industry works (very high textures with relatively low poly meshes). High resolutions work great for visual applications. If you are working on reverse engineering or plan to send your scan to a 3D printer, chances are you will want all the mesh resolution you can get. Take this coloured mesh, for instance. It looks great with texture, but it is pretty limited in geometry.

Interested in 3D scanning?

Contact our Peel 3D experts

2. Hold still, very still!

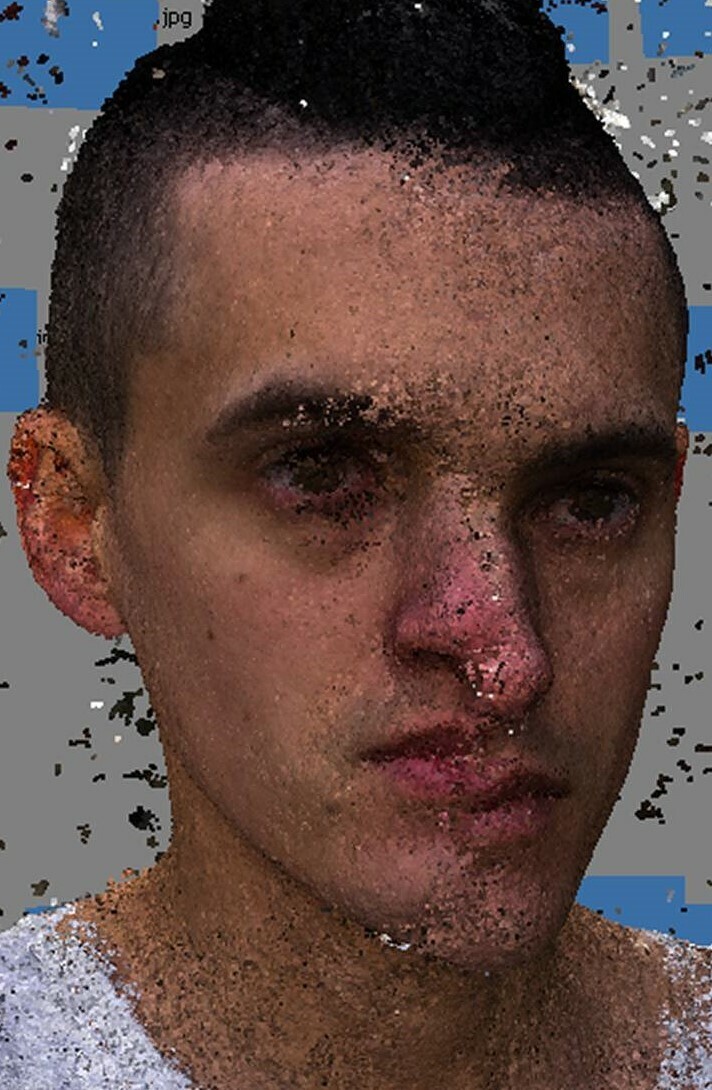

Another limitation of photogrammetry is that it requires the subject to be perfectly still. This is the reason why full body scanners need 20-30 cameras synchronized. Any slight movement will have a devastating effect on the results:

Again, it is possible to achieve amazing results with a complete rig, but this can be a costly and bulky solution.

3D scanning, on the other hand, is a lot less affected by movement as it only relies on a smaller area at the time. A handheld device also has a significantly smaller form factor, making it much easier to carry and bring it directly onsite.

3. What’s the deal with texture?

When working with photogrammetry, you take pictures of the same objects from different angles. The software then identifies features (found in the texture) and matches them in the other pictures. Being able to match these features between images from different angles is what makes the 3D surfaces. This works very well on an object with a lot of texture (like a rock)—but will produce inferior results on an object with little texture (like a car door).

A 3D scanner works better with objects with little texture as it relies on recognizing its projected pattern. Texture might disturb the detection of the light pattern making it more difficult for the scanner to work.

4. Like working with a blindfold…

Another great advantage of using a 3D scanner is to see what you are doing in real time. This lets you see the areas you’ve scanned and, more importantly, the areas you’ve missed. It is always possible to add more images to a photoscan, but you will need to process the whole model every time to know and see if you have everything you need. Processing large scans with many pictures can take a long time. This also makes the use of 3D scanning as a process significantly faster than using photogrammetry.

5. What kind of accuracy can you expect?

It is possible to obtain great-looking scans with photogrammetry—but getting good accuracy is more challenging and random as many parameters are not controlled. Cameras (even the good ones) are generally not optically calibrated for 3D scanning. This can create critical scaling errors in a 3D scan. 3D scanners (the good ones, at least) will generally be calibrated for scanning. They provide more of a controlled ecosystem, making them more predictable hence the possibility to offer accuracy specifications.

6. The difference between interior and exterior…

Again, photogrammetry works great if you can get all around the subject and take a good number of pictures, but what if you are trying to scan the interior of something in more of a confined area? Think of trying to scan the inside of a car for instance. Getting the right number of pictures of all components from all angles will be nearly impossible, making it practically unfeasible to scan the inside of an object with this technology.

This is where a 3D scanner with a small form factor will be handy. Scanning objects from all angles will be much more achievable as you can easily get them into, around or under things.

7. How much time can you invest in onboarding and training?

You hear this a lot: “Oh, the things he can do with his equipment!” Many people have the preconceived notion of being competent or qualified with a device or system. This is a system that relies on its user to deliver outstanding performance. When you know how to use it, it works pretty well. However, getting there can sometimes be painful. And if the system is to be used by more than one person, these new users must also learn all its ins and outs.

A system that does not require any training or specific scanning knowledge is, therefore, a great bet. This is the case with good 3D scanners, as they will prevent users from collecting bad-quality data and deliver great performances regardless of how they are used.

When choosing between photogrammetry and 3D scanning, you must consider your needs and applications. In some cases, and for some applications, photogrammetry is interesting, but, just like anything, it is not suited for everything.

Wonder how Peel 3D can transform your work, solve problems, and save you time?

Contact our Peel 3D expertsauthor

ABOVE MENTIONED PRODUCTS