Why should you pay more for a professional 3D scanner?

You made up your mind and decided that 3D scanning was what you needed for your application. That’s a good start! It’s time to choose which solution most fits your needs. Shopping around, you may be tempted to consider more affordable 3D scanners. Many online users are promoting that some “very good” scanners are available for $500-$600. Why would you even consider the equipment that is 10x the price? Here are a few things to remember when selecting a 3D scanning solution.

It’s all about the details!

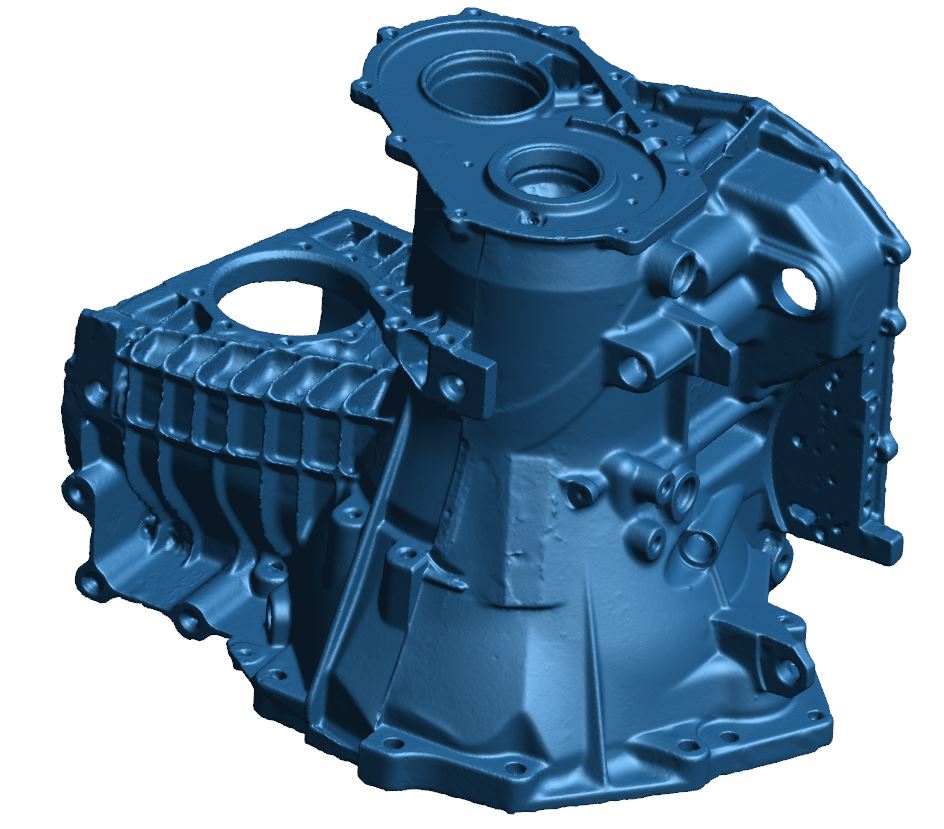

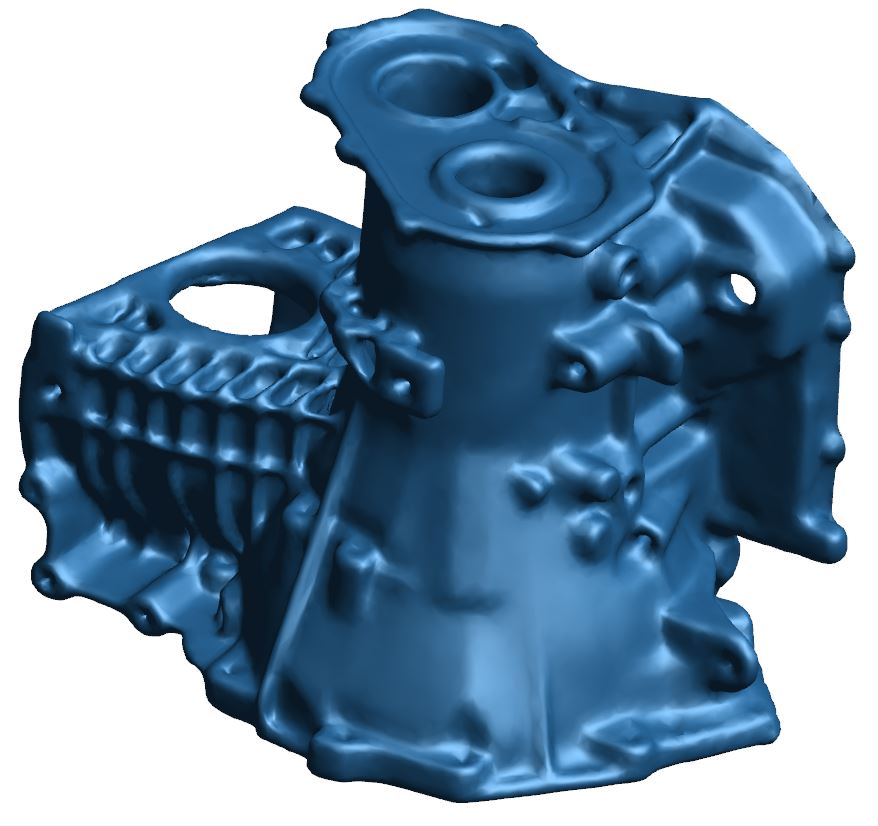

Although Kinect-like 3D scanners usually have impressive capabilities in capturing data, they are somewhat limited in resolution (the amount of detail they will capture). Scanned objects and surfaces will often look entirely smoothed out with round edges:

Figure 1: Transmission casing scanned with Peel 3D (top) and with Skanect (bottom) More resolution means a crispier, more realistic scan where more minor features will be more precisely defined and more usable.

Interested in 3D scanning?

Contact our Peel 3D experts

Is it accurate?

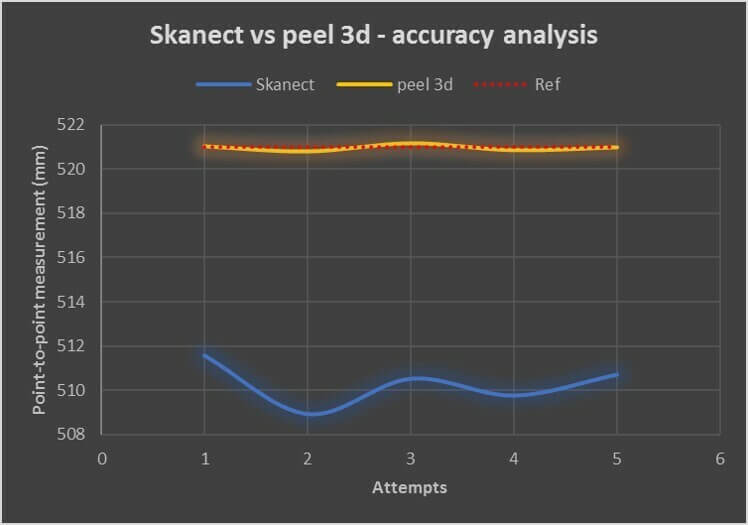

Even if a 3D scan looks nice, one should consider how close it is to the actual model. The quality of the internal components, combined with software calibration, will dramatically impact the accuracy you can reach. Critical errors are more than common on a low-cost scanner, as can be seen in the below chart:

Chart 1: Accuracy comparison between Peel 3D and Skanect.

You can use this widget to

In this test, we scanned a controlled artifact five times with each 3D scanner, extracted the reference distance (point-to-point distance between two spheres), and compared it to the controlled measurement. As seen above, a Skanect 3D scanner resulted in an average error of 10.7 mm, while Peel 3D provided an average error of 0.115 mm. The standard deviation is also significantly more minor with the Peel 3D scanner.

This means that even if a shape is recognizable when scanned with a Skanect, it can be way off regarding how close it is to the actual object. In other words, if you are trying to design something based on your scan, chances are it will not fit (or be very loose).

Like aiming with a loose cannon!

There is also the notion of how repeatable an error is. Some measurement devices will not necessarily be accurate but at least afford good repeatability. For instance, think of a system that would provide an incorrect scale factor consistently. All measures would be off—but always by the same amount (more or less). It’s not great, but at least it can be compensated in some way…

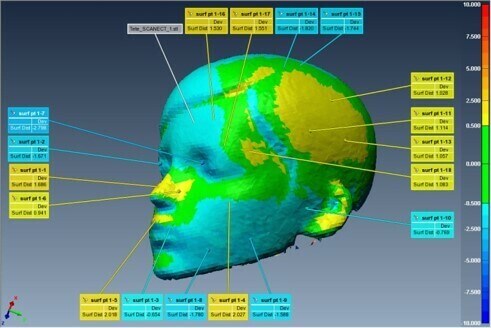

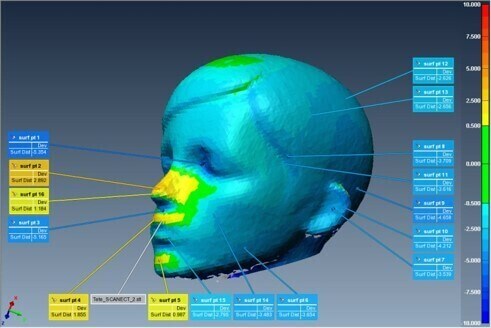

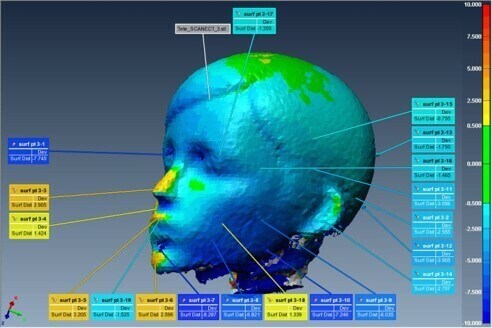

Unfortunately, this is not the case with low-end scanners, especially when it comes to complex shapes, as can be seen below. The error is randomly spread over the scanned model in an inconsistent pattern:

Figure 2: Measurement error on three scan sessions made with a Skanect scanner (warmer colours = positive errors, cooler colours = negative errors).

In this test, we compared the scan results made with a Skanect on a controlled mannequin head. As can be seen, despite following consistent measurement techniques, the errors were significant and random, sometimes exceeding and sometimes short of the reference shape by several mm.

This means that your different scans will have significant measurement differences from one scan to another—even if you scan the same object, with the same technique and in the same environment! The results you get will be random within an important range.

Things you can do with your data…

Using a 3D scanner also usually involves at least a few post-treatment steps. For instance, you will likely need to remove surrounding surfaces (to isolate your object). Moreover, you will likely need to fill areas you couldn’t scan, re-align and perform your scan again, etc. The tools included in affordable 3D scanners are usually quite limited, rudimentary and unstable.

Data finalization is essential to 3D scanning what putting is to golf; it’s half the game, and you can’t neglect one vs the other. If you plan to use your low-cost 3D scanning data, you will need to invest in additional software (i.e. add higher costs to your solution).

Almighty targets!

Finally, scanning something flat or smooth (a car door, for instance) will undoubtedly be very challenging with low-cost scanners as they generally only rely on geometry for positioning; these items barely provide any geometry information to grab onto. This means you might wind up with very poor-quality (even unusable) results.

Stick-on markers will, on the other hand, ensure the accuracy of your 3D scanner and let you accurately scan the flat or smooth surface, making it entirely usable in your application!

In the end…

Low-cost 3D scanners are not bad at all: they are an excellent place to start with and familiarize with 3D scanning. If you are a hobbyist interested in starting 3D scanning for fun, this could be a perfect place to start. Affordable scanners may even be suitable for your specific application. However, if you are working in a professional environment on commercial applications, a professional and comprehensive 3D scanning solution is best.

Wonder how Peel 3D can transform your work, solve problems, and save you time?

Contact our Peel 3D expertsauthor

ABOVE MENTIONED PRODUCTS