Get $20K Scanning Results for Half the Price.

In today's "Scan to CAD" market, choosing the right 3D scanning device can be overwhelming. The proliferation of 3D scanner models, combined with similar specifications on datasheets, makes it challenging for even experienced business owners or engineers in small to medium-sized companies to make an informed decision.

This blog post will guide you through the differences between 3D scanning technologies priced from $10K to $20K for "Scan to CAD" applications. By exploring various scenarios that designers encounter, you'll gain a clearer understanding of what to consider when selecting the right technology. We will also highlight why some opt for solutions in the $20K to $40K range for similar applications.

By the end of this article, you will be equipped to make an informed choice: opt for a cost-effective $10K solution or invest in a premium $24K solution, avoiding the unnecessary middle ground and steering clear of competitive solutions that fall in between.

Scan to CAD Goals

Professionals in product development and reverse engineering typically aim to design new parts or adapt existing ones using CAD software. Those seeking 3D scanners priced between $15K to $20K are looking for cost-effective solutions that offer sufficient performance to complete tasks efficiently and enhance existing processes. These professionals strive to outpace their competition and achieve a solid return on investment (ROI). Often, a new tool like a 3D scanner can quickly generate new revenue by reducing time to market.

Scan to CAD: A New Challenge to Consider

Traditional methods of converting a physical part to a virtual model are time-consuming. Modern 3D scanning technologies have made acquiring 3D data much faster, presenting a new challenge: how easy it is to use the data is sometimes more critical than the speed of data acquisition. It's common for designers to spend 30 to 40 hours refining a CAD model from a part that took less than an hour to digitize.

Adopt a Solution-Centric Approach

The ultimate goal of any design process is not merely to scan parts, but to obtain usable 3D models from the scan data or to design parts that fit with digitized components. Therefore, it's crucial to evaluate the entire solution's performance, including both hardware and software tools, rather than focusing solely on the scan data. A Scan to CAD solution that offers high-fidelity digitization with minimal effort and experience is ideal for budget-sensitive businesses. So why pay $20K when you can get the same experience for $10K?

The $10K Solution: Peel 3

One of the standout options in the $10K range is the Peel 3, made in North America and powered by Creaform. The Peel 3D Scan to CAD solution combines high-quality 3D scanning devices with excellent measurement capabilities, integrated into a structured workflow that guides users through every step, from measurement to typical post-treatment operations like mesh alignment, improvement, and feature editing.

What sets Peel 3 apart is its user-centric design, featuring embedded descriptions and instructional videos for each tool, which provides an unmatched user experience. This approach accelerates the overall process and ensures a short learning curve, making it accessible even for those new to 3D scanning.

By choosing Peel 3, you not only get a cost-effective solution but also benefit from a comprehensive support system that enhances productivity and reduces the time to market. It's a smart choice for businesses looking to optimize their design and reverse engineering processes without stretching your budget.

Why pay $20K when the Peel 3 offers everything you need for just $10K?

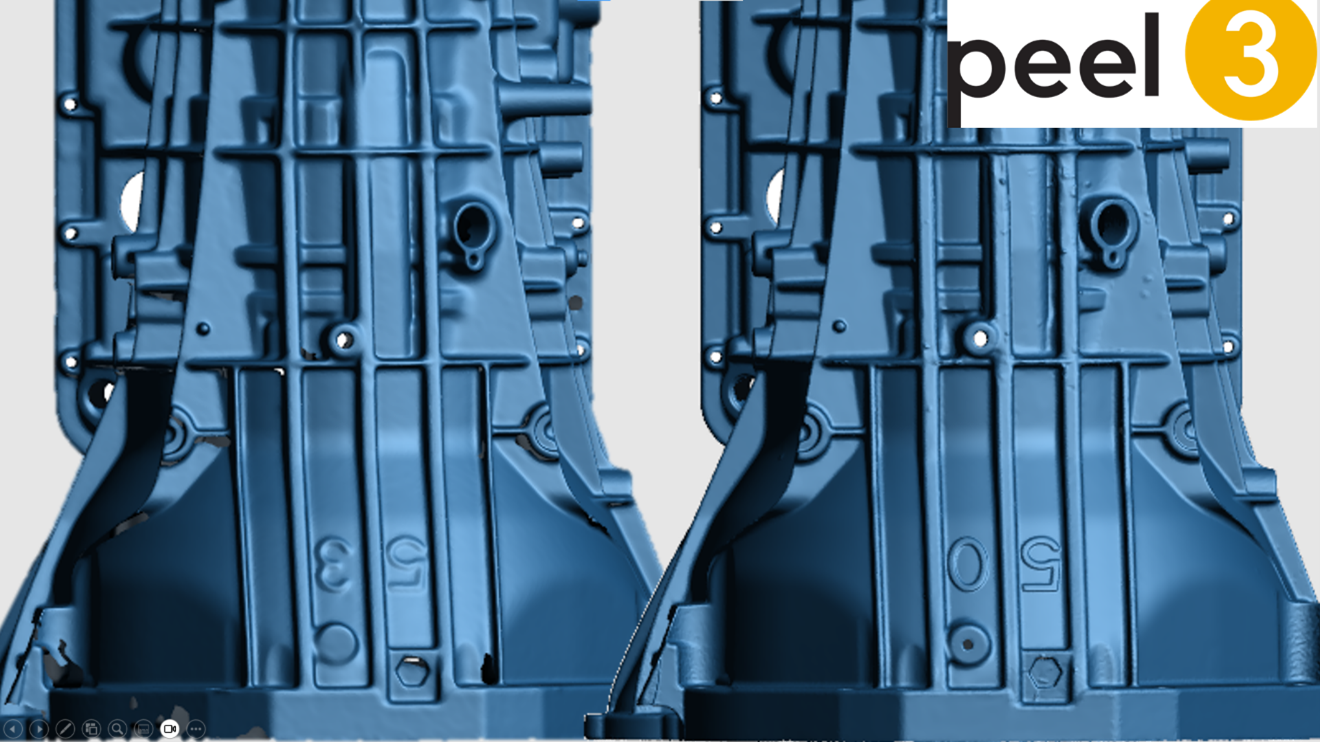

Similar transmission casting scanned with an $18K scanner vs Peel 3.

Composite part scanned with Peel 3 vs an $18K 3D scanner.

Conclusion: Invest Smartly for Maximum ROI

Choosing the right 3D scanning solution for reverse engineering and product development involves balancing various factors, including accuracy, resolution, portability, ease of use, software capabilities, speed, cost, and support. Carefully assessing these criteria against your specific project needs will help you make an informed decision.

Business owners, small businesses, and engineering departments in larger companies looking for a Scan to CAD solution with budget as a primary consideration should focus on the $10K range. Solutions like Peel 3D deliver excellent performance and comprehensive support. There is little to no advantage in selecting a device priced between $15K and $20K, as the incremental gains do not justify the extra investment.

For those requiring more accuracy, resolution, and performance on difficult surfaces, a more premium option like the HandySCAN SILVER Series from Creaform is ideal. This series offers advanced software tools that simplify the designer's workflow, making it a preferred choice for technology innovators and engineering professionals aiming to enhance product development, shorten time-to-market, and reduce development costs.

Small dark black composite part scanned with Peel 3 compared to HandySCAN SILVER Series.

In summary, whether you choose the cost-effective Peel 3 or the high-performance HandySCAN SILVER, you can rest assured that you are making a wise investment. Skip the mid-range options and opt for a solution that truly meets your needs and maximizes your ROI.

Wonder how Peel 3D can transform your work, solve problems, and save you time?

Contact our Peel 3D experts