Why “Copy” an Object with a 3D Scanner?

We often hear: “now that people have 3D scanners, aren’t you afraid they will start copying everything?” First, 3D scanners are not an enabler here; it was possible to copy existing objects long before the venue of this technology; if anything, it only took longer.

There are, however, cases where you need to work with existing parts, components or assemblies where having a virtual image of your component will save you a lot of time. Think of people modifying existing equipment and changing or improving its use.

Take the example of Ben from EMI Conception, which specializes in manufacturing high-end digging equipment for excavators from 1 to 30 tons. They also do all sorts of mechanical projects. Before getting their Peel 3D scanner, they would use traditional measuring (a mix of a tape measure and calliper) to model different existing components. Things could get creative with the use of cardboard templates and whatnot, but in the end, and with a few iterations, it always worked. Adding 3D scanning into the project was a way for them to get things right the first time with a high level of confidence.

Ben recently contacted us about a metal casting project for an airplane component. These castings used to be available as bare and would get machined to their final tolerances to reach specific higher tolerances required by the industry and be used as part of the plane cockpit. Unfortunately, in our specific case, the component was discontinued and no longer available; there is also no drawing or existing CAD file for the component either… Luckily, the owner still had a bare casting.

Interested in 3D scanning?

Contact our Peel 3D experts

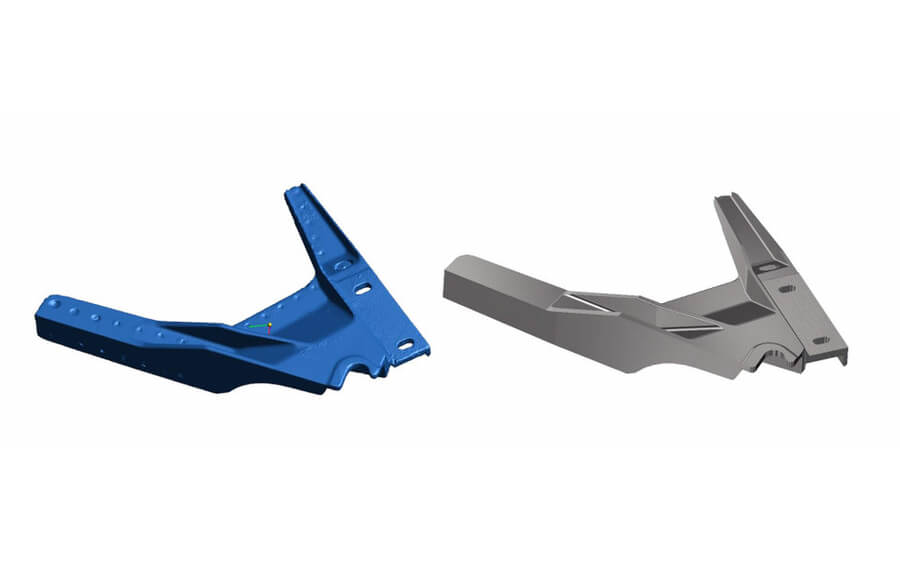

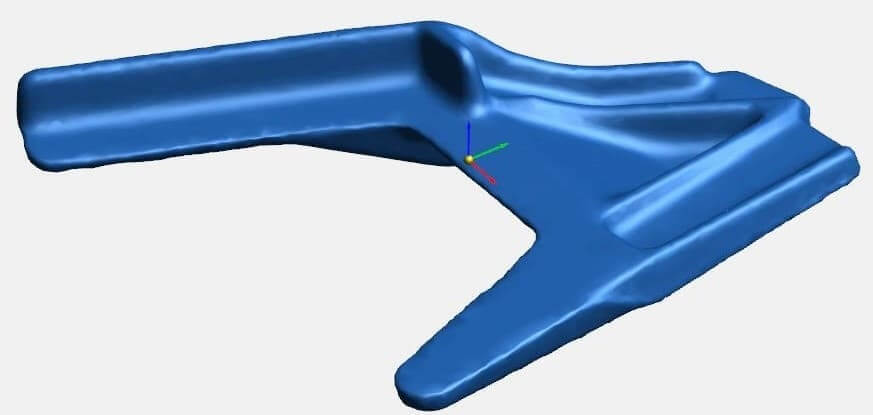

As you can see from the picture, the component has a very organic shape with very few aligned surfaces making it particularly difficult to model using traditional methods. To use Ben’s words, this is where a 3D scanner comes in handy! He started by 3D scanning the raw component to keep it as a virtual archive, should they ever need to produce additional castings.

The part was then machined to tolerance and scanned again to create a 3D solid in CAD to create drawings of the components used for machining future components. This is how the same 3D scanner was used twice on the same part but for two completely different uses; now that’s smart!

This is how making a simple copy becomes innovative and takes engineering further. Of course, a scanner good enough to be used on mechanical components could do just as well in a museum to archive artifacts or capture the shape of a residual limb in a medical clinic.

Going back to Benoit’s project, he also sent me a scan he did of a dirt bike; the scan took about a minute and provided a lot of highly valuable information that would otherwise be very difficult to get. This looks promising for his next project.

Do you have an interesting story or project to share? Contact us; who knows, it might also end up on this blog!

Wonder how Peel 3D can transform your work, solve problems, and save you time?

Contact our Peel 3D expertsauthor

ABOVE MENTIONED PRODUCTS