Revolutionizing Custom Car Audio Design through 3D Scanning

On the West Coast, in surf world renowned destination Huntington Beach, is a custom audio shop making big waves. JT and the all-star team at Automotive Entertainment HB are masters in the craft of automotive customization and one of the very bests in audio upgrades. Upon my first visit there, the guys had me sit in a retro dark red 96 Cadillac while they put on Too $hort - The Ghetto for a round of tests. I got instant goose bumps and thought to myself I was hearing that classic the proper way for the first time.

Over the past 7 years, they transitioned from traditional methods to digital, revolutionizing their clients’ experience. This pivotal decision marked a significant leap forward for the company. Initially rooted in cardboard tracing and resin fiberglass, they first shifted their process towards 3D printing their molds. Then, they integrated 3D scanning to their workflow.

Getting additional precision to cut down on trial and errors was not the only factor weighing in their decision to upgrade their method: the use of resin chemicals from traditional molds would compromise the distinctive smell of new cars. By opting for 3D scanning and 3D printing, the team ensured a cleaner working environment, preserving the cherished scent of a client's vehicle.

On the scanning side of things, Automotive Entertainment HB initially purchased a Peel 3d scanner and then upgraded to the HandySCAN 3D|BLACK Elite by sister brand Creaform for outstanding accuracy, resolution and the ability to scan any type of surfaces without any prep. … even chrome. The integration of these new tools and process was supported in part by Jeremy Katz from JK Automotive Designs who’s known for building amongst the finest automotive interiors.

Automotive Entertainment HB most recently showcased their skills on a limited-edition Bugatti. That project presented unique challenges, given the exclusivity of the Bugatti model (only 60 units worldwide). The primary goal was to ensure that any modifications made were reversible, allowing the owner the option to sell the vehicle in its original factory form. The commitment to authenticity remained paramount throughout the project.

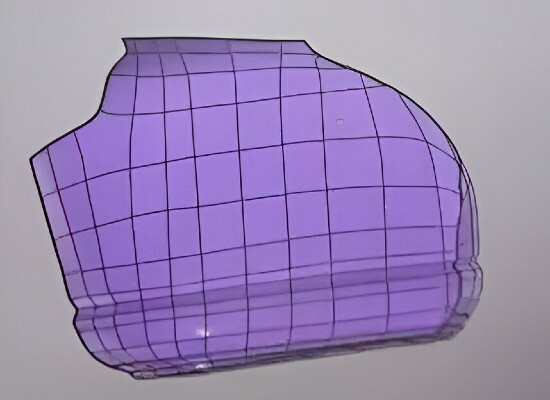

The work began by delicately removing the leather to expose the speaker pocket to be scanned. An original speaker grill could then be printed for the new housing based on the cross-sections and nurbs surfaces extracted from the scan. Being able to replicate organic curvature easily with these nurbs surfaces extracts has been another one of the key benefits from working with Peel 3d and Creaform tools.

Original door interior

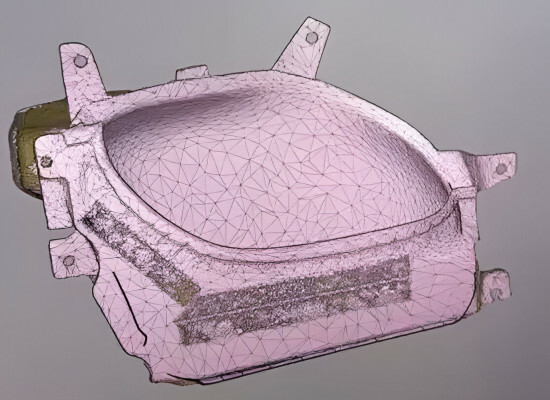

Scan data from the door interior with the new speaker grill design

Speaker pocket mesh from scan

Nurbs surface from 3d scan data

As Automotive Entertainment HB continues to blend innovation with tradition, their work on projects such as the limited-edition Bugatti serves as a testament to their commitment to excellence. Keep a close watch as Automotive Entertainment HB explores new frontiers to the beat of their own drum.

Writer: Marie Simard, Business Development Manager, USA

Wonder how Peel 3D can transform your work, solve problems, and save you time?

Contact our Peel 3D experts